China Supplier Laminated Glass Backsplash - Laminated Glass – Yongyu

China Supplier Laminated Glass Backsplash - Laminated Glass – Yongyu Detail:

Basic Info

Laminated glass is formed as a sandwich of 2 sheets or more float glass, between which is bonded together with a tough and thermoplastic polyvinyl butyral (PVB) interlayer under heat and pressure and pull out the air,and then put it into the high-pressure steam kettle taking advantage of high temperature and high pressure to melt a remaining small amount of air into the coating

Specification

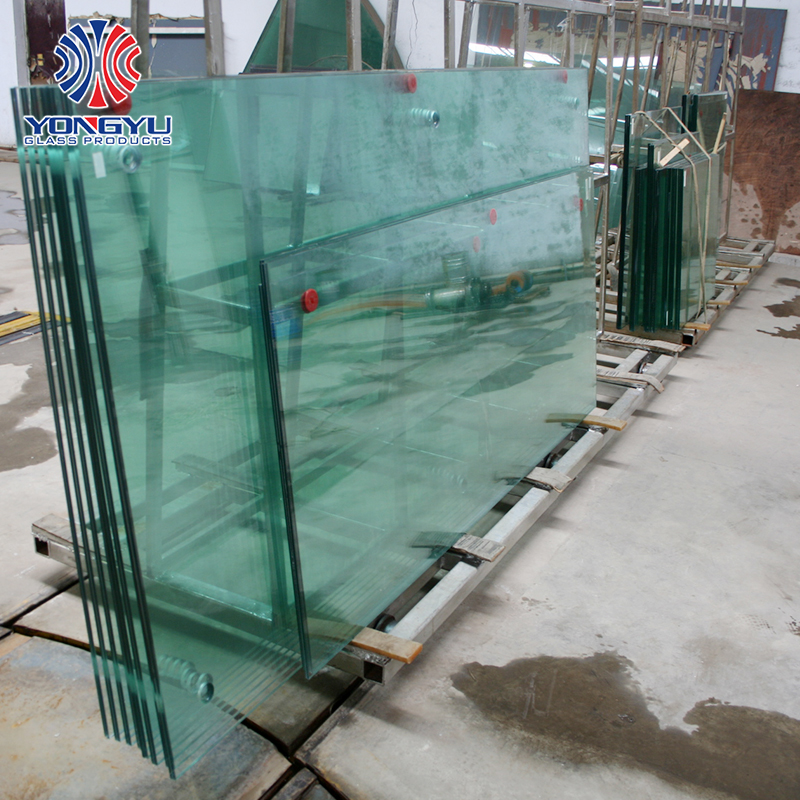

Flat laminated glass

Max. size:3000mm×1300mm

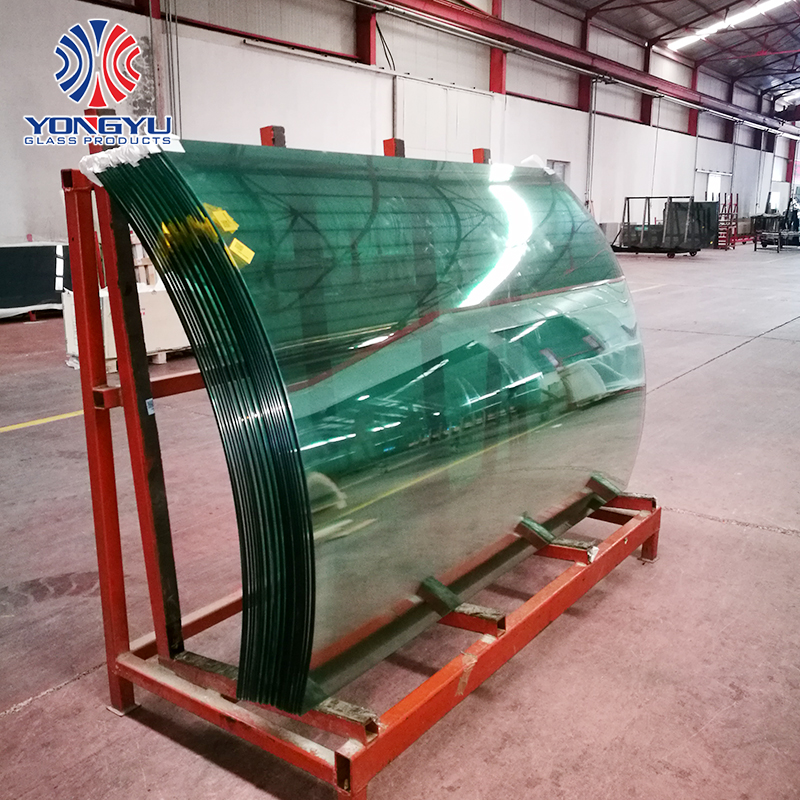

Curved laminated glass

Curved tempered laminated glass

Thickness:>10.52mm (PVB>1.52mm)

Size

A. R>900mm, length of arc 500-2100mm, height 300-3300mm

B. R>1200mm, length of arc 500-2400mm, height 300-13000mm

Other Advantages

Safety: When laminated glass is damaged by an external force, the glass fragments will not splash, but remain intact and prevent penetration. It can be used for various safety doors, windows, lighting walls, skylights, ceilings, etc. It can also be used in earthquake-prone and typhoon-prone areas to reduce damage caused by natural disasters.

Sound Resistance: PVB film has the property of blocking sound waves, so that laminated glass can effectively block sound transmission and reduce noise, especially for low-frequency noise.

Anti-UV Performance: laminated glass has high UV blockage performance (up to 99% or more), so it can prevent the aging & fading of indoor furniture, curtains, displays, and other items.

Decorative: PVB has many colors. It gives rich decorative effects when used together with coating and ceramic frit.

Laminated Glass vs. Tempered Glass

Like tempered glass, laminated glass is considered a safety glass. Tempered glass is heat treated to achieve its durability, and when struck, tempered glass breaks in to smooth-edged small pieces. This is much safer than annealed or standard glass, which can break into shards.

Laminated glass, unlike tempered glass, is not heat treated. Instead, the vinyl layer inside serves as a bond that keeps the glass from shattering into large shards. Many times the vinyl layer ends up keeping the glass together.

Product display

|

|

|

|

|

|

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for China Supplier Laminated Glass Backsplash - Laminated Glass – Yongyu , The product will supply to all over the world, such as: Poland, Denver, Cairo, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.