Vacuum Glass

The Vacuum Insulated Glass concept comes from the configuration with the same principles as the Dewar flask.

The vacuum eliminates heat transfer between the two glass sheets due to gaseous conduction and convection, and one or two internal transparent glass sheets with low-emittance coatings reduce radiative heat transfer to a low level. The world’s first VIG was innovated in 1993 at the University of Sydney, Australia. VIG achieves a higher thermal insulation than conventional insulating glazing (IG Unit).

Major Benefits of VIG

1) Thermal insulation

The vacuum gap significantly reduces conduction and convection, and the low-E coating reduces radiation. Only one sheet of low-E glass allows more natural light into the building. The temperature of VIG glazing toward the inside is close to room temperature, which is more comfortable.

2) Sound insulation

Sound cannot transmit in a vacuum. VIG panes significantly improved the acoustic attenuation performance of windows and facades. VIG can better reduce medium and low-frequency noises, such as road traffic and life noise.

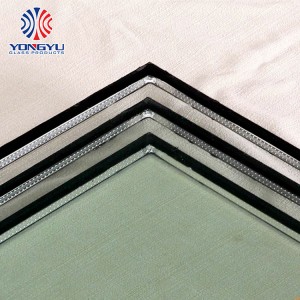

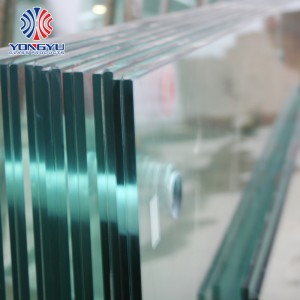

3) Lighter and thinner

VIG is much thinner than the IG unit with air space instead of a 0.1-0.2 mm vacuum gap. When applied to a building, the window with VIG is much thinner and lighter than that with the IG unit. VIG is easier and more efficient than triple-glazing to lower the U-factor of the window, especially for passive houses and zero-energy buildings. For building restoration and glass replacement, the thinner VIG is preferred by owners of old buildings, as it has higher performance, energy savings, and durability.

4) Longer life

Our VIG’s theoretical life is 50 years, and the expected life can reach 30 years, approaching the life of door, window, and curtain wall frame materials.